What are corrugated boxes? If you’re still not familiar with the world’s best packaging option, then you’re in the right place. Read on to learn more about what corrugated boxes are as well the different uses for and types of corrugated packaging.

In order to understand what corrugated boxes are, you first have to understand how they’re made. Made predominantly from trees, which are a renewable resource, corrugated packaging is the most recovered packaging material on the planet. It is sustainably manufactured from trees and old recovered corrugated containers with an industry recovery rate hovering around 90% over the last eight years and 96 percent in 2018 per expert reports.

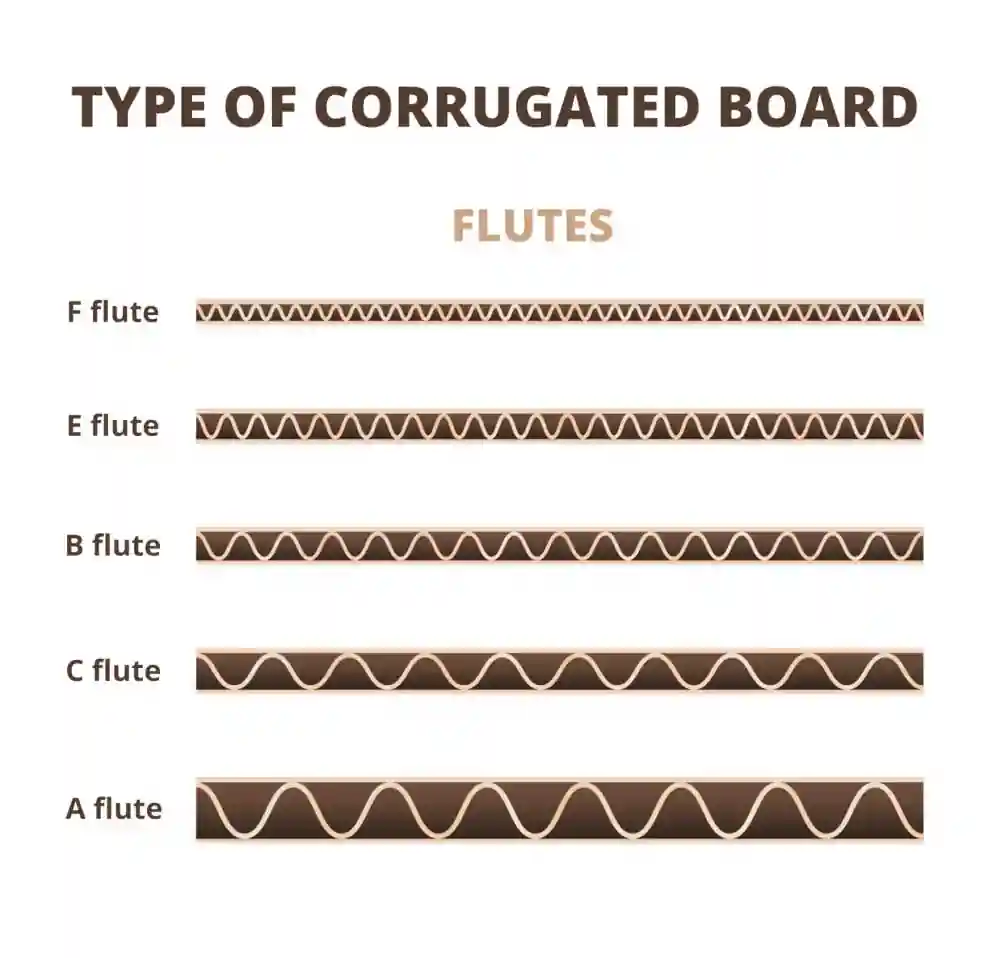

The most common flutes used today are A, B, C, E, and F, with A being the largest flute size. Flute size determines the thickness of the walls as well as the stacking strength of your corrugated box.

An “A” flute is approximately 5 mm thick and is an ideal option for products that require additional cushioning or extra strength for stacking.

As you go through B, C, E, and F flutes, the thickness is smaller resulting in a thinner board.

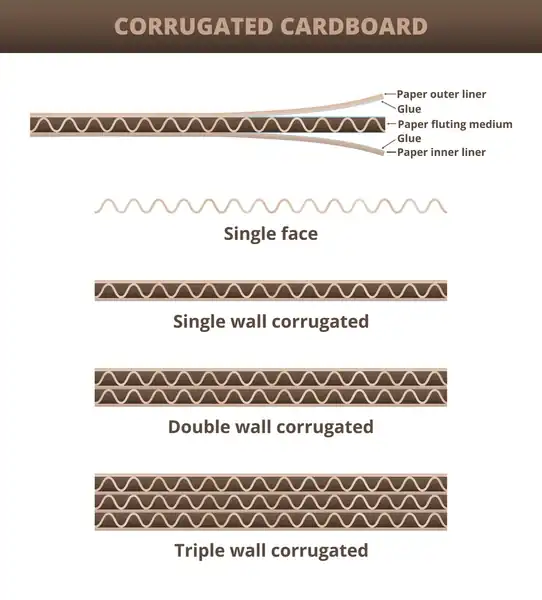

There are four types of boards that can be used for corrugated boxes. The most common of which are single-wall and double-wall boards.

There is also single-face board which is made up of one sheet of liner adhered to one sheet of corrugated medium. This style of board is typically sold in rolls and can be used to wrap around products for protection and cushioning.

Single-wall board is when one sheet of corrugated medium is glued between two sheets of liner. Single-wall is the most common type of board in the market and can be used for everything from shipping boxes to retail displays.

Double-wall is when two sheets of corrugated medium are glued between three sheets of liner. This board is commonly used for heavier products or products that require a stronger box for shipping.

And lastly, triple-wall is when three sheets of corrugated medium are glued between four sheets of liner. This board is the strongest out of all the board styles and is often used for industrial parts or produce bins.

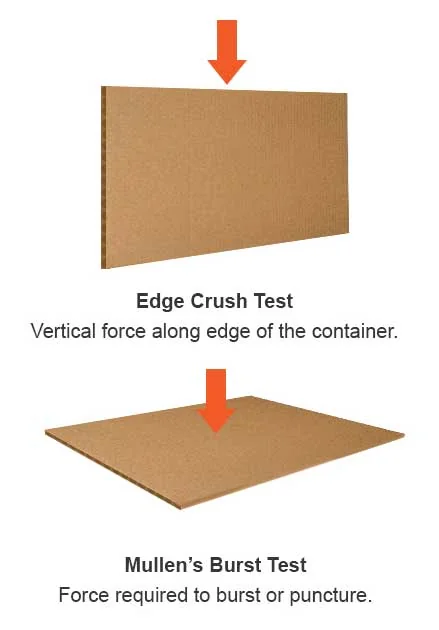

Corrugated board is categorized as either Mullen or Edge Crush Test (ECT). These two board grades have very different applications. ECT measures how much stacking strength or pressure a box can withstand before being crushed. ECT board is the favourable choice if you’re going to be stacking boxes on top of one another, whether on a pallet or warehouse shelf.

Mullen value is determined by the amount of pressure a box can withstand before bursting or being punctured. If you’re looking for resistance from internal or external factors, this is the board type you’ll want.